Rubber Bands

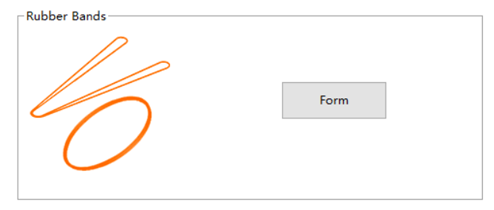

1. Form

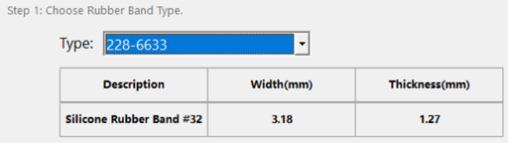

1.1 Select the product number from the drop-down box and choose the type of rubber band you need. You can also view the name, width, thickness or diameter of the rubber band.

More Information

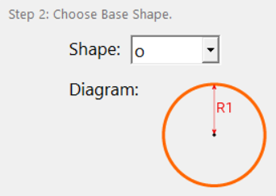

1.2 Use the drop-down box to select the basic shape you need for rubber band forming: o, 0, Δ, v-Δ, v-▽, □, U. (The following instructions are in mm)

① In o design, the following conditions are met:

• R1 ∈ [1,60]

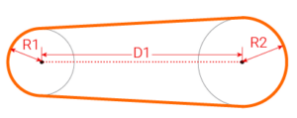

② In 0 design, the following conditions are met:

• R1,R2 ∈ [1,60]

• D1 ∈ [9,610]

• D1>|R1-R2|

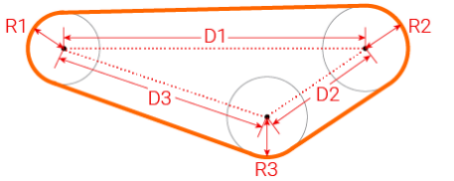

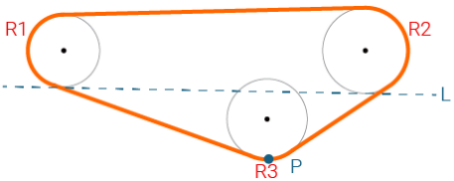

③ In Δ design, the following conditions are met:

• R1,R2,R3 ∈ [1,60]

• D1,D2,D3 ∈ [9,610]

• Any D is greater than the absolute value of the difference between the two radii.

• The sum of any two sides of the triangle formed by D1, D2, and D3 must be greater than the third side.

• The vertex P of the R3 circle on the rubber band must be below the lower tangent L of the R1 R2 circle.

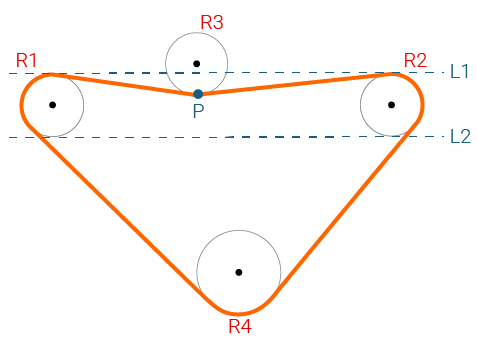

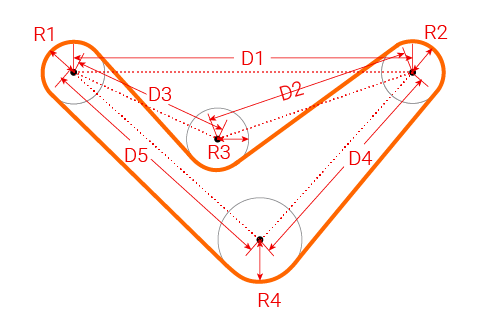

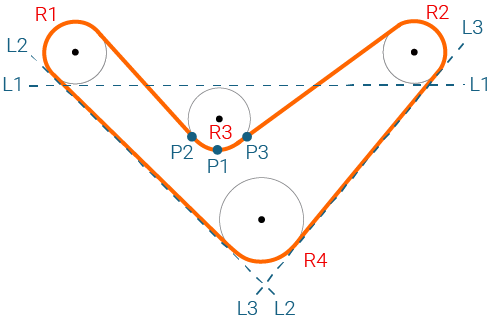

④ In v – Δ design, the following conditions are met:

• R1,R2,R3 ∈ [1,60]

• D1,D2,D3 ∈ [9,610]

• Any D is greater than the absolute value of the difference between the two radii.

• The sum of any two sides of any triangle must be greater than the third side.

• R1 R2 R4 satisfies the design of Δ.

• R3 The vertex P of the circle on the rubber band must be between the upper tangent L1 and the lower tangent L2 of the circle R1 R2.

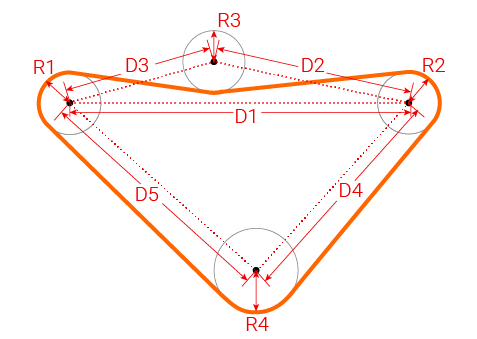

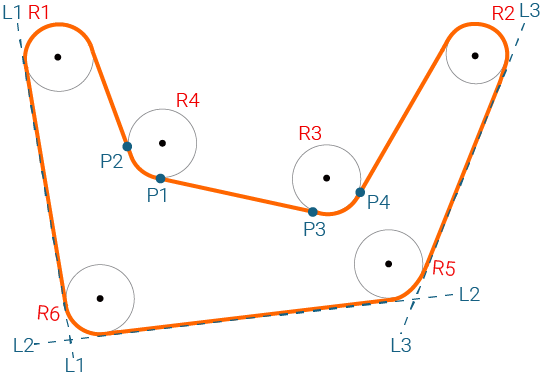

⑤ In v – ▽ design, the following conditions are met:

• R1,R2,R3,R4 ∈ [1,60]

• D1,D2,D3,D4,D5 ∈ [9,610]

• Any D is greater than the absolute value of the difference between the two radii.

• The sum of any two sides of any triangle must be greater than the third side.

• R1 R2 R4 satisfies the design of Δ.

• P1 must be below the tangent L1, P2 must be to the right of the tangent L2, and P3 must be to the left of the tangent L3.

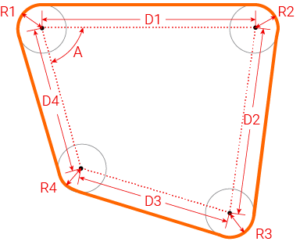

⑥ In □ design, the following conditions are met:

• R1,R2,R3,R4 ∈ [1,60]

• D1,D2,D3,D4 ∈ [9,610]

• A∈ (0,180)

• Any D is greater than the absolute value of the difference between the two end radii.

• R1 R2 R3 satisfies the design of Δ, R1 R2 R4 satisfies the design of Δ.

• R1 R3 R4 satisfies the design of Δ, R2 R3 R4 satisfies the design of Δ.

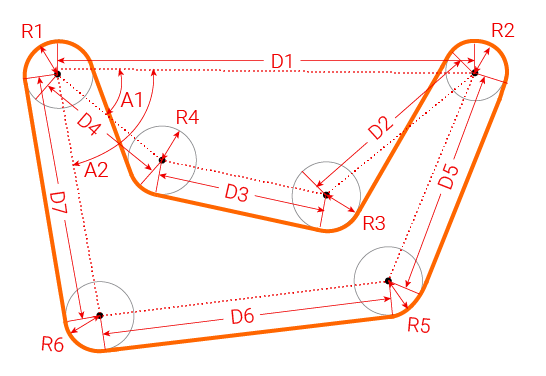

⑦ In U design, the following conditions are met:

• R1,R2,R3,R4,R5,R6 ∈ [1,60]

• D1,D2,D3,D4,D5,D6,D7 ∈ [9,610]

• A1,A2 ∈ (0,180)

• Any D is greater than the absolute value of the difference between the two end radii.

• R1 R2 R5 R6 satisfies the design of □, R1 R2 R3 R4 satisfies the design of □.

• P1, P3 must be above the tangent L2, P2 must be on the right side of the tangent L1, and P4 must be on the left side of the tangent L3.

1.3 Design the parameters for “Radius”, “Distance”, “Angle”.

① “Radius” range: 1~60mm / 0.04~2.36inch.

② “Distance” range: 9~610mm / 0.35~24inch.

③ “Angle” range: 0~180°.The value can only be integers.

1.4 Click the “Generate Now” button.

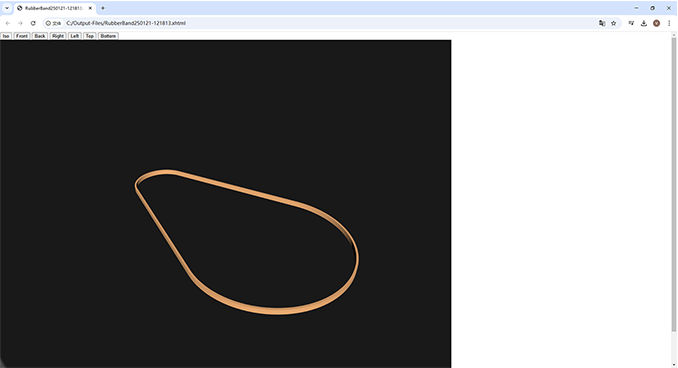

① If “Preview (HTML)” is selected in the settings, a browser preview will automatically pop up after normal generation, allowing you to view your design in all directions.

② After normal generation, go to the STEP file generation address with one click according to the pop-up prompt.